Stair refurbishment and coating system

Stair refurbishment and coating system

For external stair refurbishment we are using fast-curing repair mixtures and liquid plastic coating. This allows work to be done quickly which shortens residents discomfort time considerably. You can walk on the stairs no later than 1 hour after the end of the work. Liquid-plastic external stair system is cold-applied, water- and weather-resistant and raises the existing stair height minimally, which is important for the opening of doors.

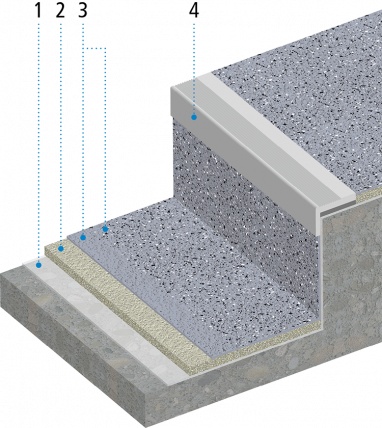

The renovation of the stair takes place in several stages: the repair of the substructure, grinding and cleaning of the substrate and the installation of waterproof coating and finishing layers.

Triflex TSS system is suitable as a protective and decorative coating for external stairs, which acts as a shield against mechanical loads and weathering. Result is even and non-slip surface where is safe to step on. Adding sand or granite to the last layer helps to prevent slipping. Additionally for top layer, we can offer a variety of options. More information on the design and layout page.

- We remove loose concrete, repair rusty reinforcement and perform corrosion protection together with concrete repair mixtures

- Building new slopes if necessary so that the there are no standing water on the stair

- Cleaning concrete surfaces from dirt before installing coating. We use a sandblasting or grinding method

- Waterproof layers and rough surface with sand or granite sprinkles. Options for different colours, patterns and shapes

Use cases:

- Exterior stairs and landings, stairwells and concrete slabs

- New stairs. In the new building, waterproof liquid plastic is installed directly on the concrete structure. The slopes are built beforehand

- Old stairs. We repair the old structure with repair compounds or epoxy mortar and apply liquid plastic coating. Liquid plastic stair coat raises the steps height minimally and you can still open the door. Most stair constructions are suitable as substrates: concrete, stone, plywood, wood, metal and many others

Replace stair tiles with a liquid plastic pattern

Installing tiles on outdoor stairs is not the best finishing solution in our climate, because external tile tiles tend to come off the substrate in a few years. Alternatively, we offer a liquid plastic coating, where you can design a grid of tiles or other shapes on the surface to your liking. Visually, it remains the same as real exterior stair tiles. For top layer, we can offer a variety of options. More information on the design and layout page.

The main advantages of stair liquid plastic system:

- Fire safe during installation. No fire is used during installation. Sealing joints with bitumen is fire hazardous job, as a fire flame can ignite elements of a roof or wall structure hidden through openings and cracks during work.

- Fast-curing. Each applied layer hardens in 15 minutes to 1 hour, depending on the temperature. Stair usage is not obstructed for a long time

- Resistant to salts used to melt ice and snow. See “Stair Maintenance“

- 100% adhesion to the substrate

- Diversity of uses. Can be used on virtually all solid substrates, regardless of shape

- Homogeneous and seamless waterproof layer

- Many colours and the options for surface structures. See the selection of colours

System components:

- Primer

- Watertight coating

- Anti-slip finish and decorative design

- Edge profile for protection

Design and overlay options

For a top layer, we can offer a variety of options. More information on the design and layout page.

- Chips Design. As a top layer, we apply an even and smooth paint coating with a option to add chips

- Colour Design. The coloured fine dressing mixture spread onto suitable finish colours and then covered with varnish

- Stone Design. As a top layer, we install decorative marble and granite gravel. Fine or coarse fraction

- Creative Design. We design the top surface into a “tiled floor”. Remains visually similar to the real balcony floor tiles

- FloorTattoos. If you want the floor of your terrace, balcony or the loggia to be truly unique and interesting, we will install different shapes and logos on the finishing layers listed above.

Anti-slip coating

The safety of your step on the stairs must be guaranteed as much as possible. The rough anti-slip surface of the stairs can be made with sand or granite gravel of different grain sizes. However, the larger the grain size, the more non-slip the stair can be, but at the same time the larger grain makes the surface of the stairs more difficult to clean.

Stair maintenance and de-icing

Liquid plastic systems are designed to be as maintenance-free as possible. However, in the interests of good housekeeping, it is advisable to inspect the surfaces at least twice a year, ideally in spring and autumn. Visually inspect all details to identify any loose areas where water can enter. It is recommended to use de-icing agents that dissolve and do not leave unpleasant dirty residues on the stairs.

- Triflex stair system is resistant to conventional anti – icing agents, including:

• Rock salt (white preferable)

• Sodium Acetate based de-icers

• Potassium Acetate based de-icers

• Calcium Chloride Flakes

• Prilled Urea

Warranty

The lifespan of the systems according to the ETA certificate is 25 years. In complete renovation and new stairs, we give a 10-year guarantee for our work. By agreement, we regularly inspect and maintain the work performed, which extends the warranty period.

Triflex TSS stair system properties:

- The stair coating system is based on PMMA (polymethyl methacrylate) resin

- Suitable for many substrates: plywood, ceramic tiles, asphalt, concrete, PVC, TPO, PIB, polyurethane (PU), polyurea (PUA), EPDM, SBS bitumen, glass, wood, sheet metal, stainless steel, various metals and many others

- Mechanically strong and wear-resistant. Resistant to high mechanical loads and point loads of table and chair legs on the floor without breaking the ground

- Anti-slip surface. By adding sand it is possible to achieve a non-slip surface. The larger the sand grain size, the rougher the surface

- Minimal application temperature is 0°C

- Fast-curing. You can walk on the stair as early as 1 hour after the end of the work.

- Hydrolysis resistant. Suitable for zero slope surfaces, as it does not react with water and can withstand standing water

- Seamless, which further eliminates the possibility of water penetration

- Rain proof after 30 minutes

- Weather proof (UV, IR, etc.)

- European Technical Assessment according to ETAG 005 with CE mark

- Protection of concrete structures in compliance with EN 1504 / DIN V 18026

- Fire classification in compliance with EN 13501-1: Class E

- S1 version is a flame-retardant waterproofing system: EN 13501-1: Class Cfl – s1

Contact us or come to visit

If you need advice or help from men who just don't talk but actually do, write or call us.