Waterproofing junctions, joints & details

Roof junctions, joints and details waterproofing

What service do we offer?

We waterproof new and existing junctions, joints and details in the external parts of a building with liquid plastics material, which is often not possible using traditional materials and sealing sleeves. The problems are similar for tin roofs and flat roofs. The waterproofing life of roof penetrations is not comparable to the entire life of the roof, as the joints are always under a higher load due to the movement and thermal expansion of the building. The thermal expansions between contacting materials are different and start to tear the joint. In some cases, it is reasonable, for example, to seal the chimney junction with flashing or with the corresponding sealing sleeves of the sewer ventilation pipe, but a very good solution is liquid plastic, which adheres on to the entire surface to be covered.

- We improve and fix the waterproofing of various structures with liquid plastic. Metal, PVC and SBS bitumen roofs and pitched roofs with other coverings, flat roofs, balconies, loggias, terraces and external stairs

- Sealing the roof penetrations of any element or part. Sealing cables what are coming through the balcony or terrace floor and foundations during or after construction

- Complexly shaped surfaces, elements and details. Liquid plastic is applicable in liquid form, which gives an advantage over other materials, as it can be formed on intricately shaped surfaces and thus ensure water resistance

- Tubes, antenna rods, support legs, mounting bolts and the like waterproofing

- Chimney roof penetration waterproofing

- Skylight waterproofing

- Repairing flashing with liquid plastic

- Sewer ventilation pipe roof penetration waterproofing

- Wall, window, door and floor junction waterproofing

- Not easily accessible places. With liquid plastic, we can ensure waterproof surfaces even in less accessible areas

- Roof gully and other rainwater system components water resistance repair and replacement

What liquid plastics we use?

In cooperation with the German material manufacturer Triflex, we use PMMA liquid plastic waterproofing to repair roofs and eliminate problems. The material is cold-applied in liquid form with fabric or fiber reinforcement, fast curing, weather resistant and adheres to many substrates, regardless of their shape. The finished surface remains elastic, without joints and adheres to 100% of the substrate, which ensures long-term water tightness.

Combines with other liquid plastic solutions on roofs and balconies.

The main advantages of liquid plastic

- Fire safe during installation. No fire is used during installation. Sealing joints with bitumen is fire hazardous job, as a fire flame can ignite elements of a roof or wall structure hidden through openings and cracks during work.

- 100% adhesion to the substrate

- No sealing sleeves or mounting brackets needed for waterproofing

- Diversity of uses. Can be used on virtually all solid substrates, regardless of shape

- Homogeneous and seamless waterproof layer

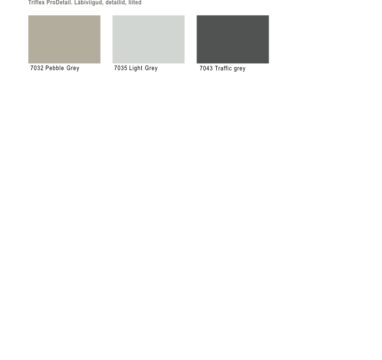

- Tintable and the possibilities of different surface structures. Can give the same appearance as adjacent surfaces. See the selection of colours

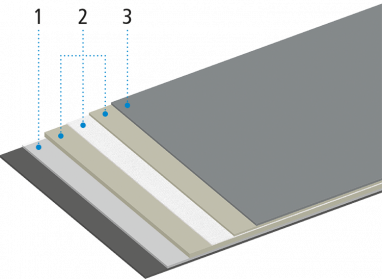

System components:

- Primer

- Waterproofing with fabric

- Finish with different colours

Colours

Waterproofing is available in three colors. We apply an even and smooth paint coating as the top layer. The paint coating is only necessary if you want to change the color of the waterproofing.

System properties:

- The liquid plastic material used is Trifle ProDetail. PMMA (polymethyl methacrylate).

- Can be applied on many different surfaces – plywood, ceramic tiles, asphalt, concrete, PVC, TPO, PIB, polyurethane (PU), polyurea (PUA), EPDM, SBS bitumen, glass, wood, metal and many others.

- Root resistance according to EN 13948 and Germany FLL test standards.

- Minimal application temperature is -5°C.

- Fast curing. Do not have to wait very long to use the area. Only an hour after finishing, it can be used.

- Seamless, which further eliminates the possibility of water penetration.

- Hydro isolation is applied with strengthening fleece which leaves an elastic layer that has crack bridging properties.

- Solvent-free.

- Rain proof after 30 minutes.

- Weather proof (UV, IR, etc.).

- Alkali resistant. Tolerates mineral materials.

- Hydrolysis resistant. Does not dissolve in water.

- Can be used on vertical surfaces.

- European Technical Assessment according to ETAG 005 with CE mark.

- Resistant to sparks and radiant heat in compliance with EN 13501-5: BRoof(t1), BRoof(t2), BRoof(t3), BRoof(t4).

- Fire classification in compliance with EN 13501-1: Class E.

Warranty

There are a lot of activity on the roof throughout its life. Electricians go there to install cables, antennas and heavy equipment, drill holes for various reasons and make other roof penetrations. Such activities must always be accompanied by a competent person or company with the competence of the respective roof. Otherwise, the roof will lose its warranty or the building will be damaged by water after some time.

- The possibility and length of the warranty for the performed repair work depends on the object and the nature of the works

- The warranty for sealing details, joints and junctions is up to 5 years

Contact us or come to visit

If you need advice or help from men who just don't talk but actually do, write or call us.