Balcony, terrace and loggia waterproofing

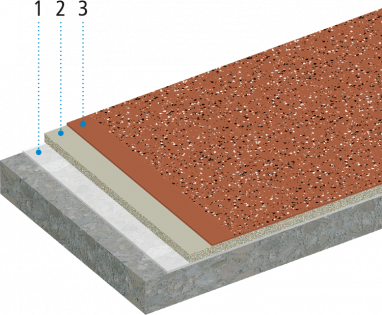

Liquid plastic system for stable substrates

Triflex BFS is a waterproof balcony flooring system. The system consists of a thick wear-resistant layer covered with a decorative coating. The balcony is a protruding part of the building or loggia that forms part of a house and has one side open and there are no heated enclosed spaces under it, which would cause large temperature differences. The structure is usually a monolithic slab. Such substrate conditions can generally be considered as stable for waterproofing layers and are a good conditions for making the balcony floor waterproof. Reinforced and resilient waterproofing is used to make all joints, transitions to other materials and cracks separately watertight. Throughout the entire surface there is a 2-3 mm watertight and static crack bridging coating. It is cast by the cold installation method and can be painted and designed in a suitable tone and pattern.

Triflex BFS is a waterproof balcony flooring system. The system consists of a thick wear-resistant layer covered with a decorative coating. The balcony is a protruding part of the building or loggia that forms part of a house and has one side open and there are no heated enclosed spaces under it, which would cause large temperature differences. The structure is usually a monolithic slab. Such substrate conditions can generally be considered as stable for waterproofing layers and are a good conditions for making the balcony floor waterproof. Reinforced and resilient waterproofing is used to make all joints, transitions to other materials and cracks separately watertight. Throughout the entire surface there is a 2-3 mm watertight and static crack bridging coating. It is cast by the cold installation method and can be painted and designed in a suitable tone and pattern.

Also suitable for covering concrete slabs or landing at the front of exterior doors or terrace structures next to the house. It can be used as an alternative to a patio or ceramic tile. We can replace the detached balcony floor tiles with decorative liquid plastic. More information on the design and layout page.

All balcony surfaces, joints and overlaps, which are necessary to ensure water tightness, merge into a uniform seamless mass.

Balcony flooring is based on PMMA (polymethyl methacrylate) resin, which is fast-curing and weatherproof.

System components:

- Primer

- Watertight coating

- Finish and decorative design

Use cases:

- Balconies, loggias, concrete slabs, landings at the doors, walkways and pedestrian bridges.

- As an alternative solution. The detached balcony floor tiles can be replaced with decorative liquid plastic.

- New constructions. In the new building, waterproof liquid plastic is installed directly on the concrete panel. The slopes are built beforehand

- Old constructions. Good for waterproofing and renovating the old balcony floor. Liquid plastic balcony coating raises the floor height minimally and you can still open the doors and windows. The substrate can be plywood, ceramic tiles, asphalt, concrete, PVC, TPO, PIB, polyurethane (PU), polyurea (PUA), EPDM, SBS bitumen, glass, wood, sheet metal, stainless steel, various metals and many others.

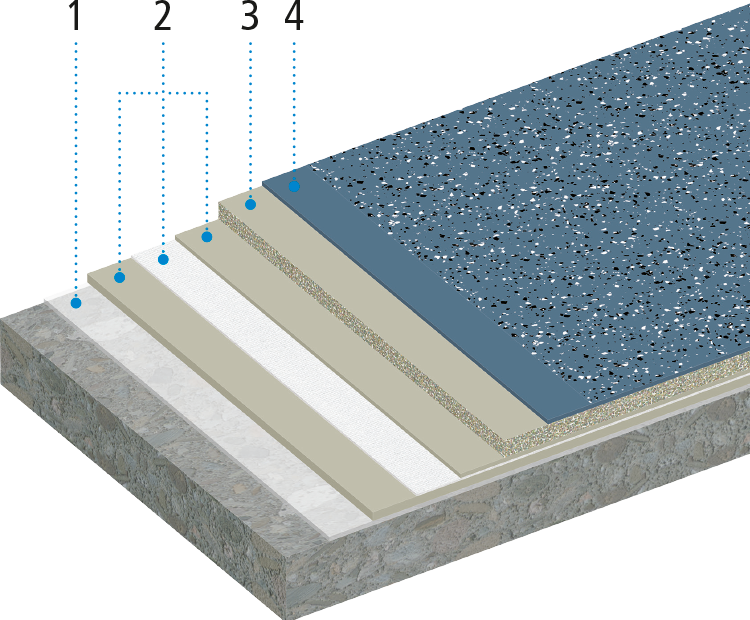

Liquid plastic system for unstable substrates

Triflex BTS-P is a waterproof terrace, loggia and balcony flooring system with reinforced waterproofing. Suitable as a complete waterproofing and wear-resistant decorative solution, where it is necessary to make reinforced waterproofing over the entire surface. The terrace, including the roof terrace, is a structure that is structurally connected to the building and there are generally heated enclosed spaces under it, which facilitates the movement of the substrate. Due to the difference in temperatures between the inner and outer surfaces, the additional load on the structure is significantly higher than in open structures. Such a construction requires greater water resistance and stronger waterproofing of the terrace. The system protects the structures, rooms and property below from the weather and at the same time looks good with different finishes. More information on the design and layout page.

Triflex BTS-P is a waterproof terrace, loggia and balcony flooring system with reinforced waterproofing. Suitable as a complete waterproofing and wear-resistant decorative solution, where it is necessary to make reinforced waterproofing over the entire surface. The terrace, including the roof terrace, is a structure that is structurally connected to the building and there are generally heated enclosed spaces under it, which facilitates the movement of the substrate. Due to the difference in temperatures between the inner and outer surfaces, the additional load on the structure is significantly higher than in open structures. Such a construction requires greater water resistance and stronger waterproofing of the terrace. The system protects the structures, rooms and property below from the weather and at the same time looks good with different finishes. More information on the design and layout page.

All balcony surfaces, joints and overlaps, which are necessary to ensure water tightness, merge into a uniform seamless mass.

Balcony and terrace flooring is based on PMMA (polymethyl methacrylate) resin, which is fast-curing and weatherproof.

Triflex BTS-P system is also used as the top layer for the Triflex BIS roof terrace system. Waterproofing of the terrace with a decorative coating.

System components:

- Primer

- Reinforced waterproofing

- Watertight coating

- Finish and decorative design

Use cases:

- Balconies, loggias, terraces, roof terraces, walkways and pedestrian bridges located on top of other rooms.

- New constructions. In the new building, waterproof liquid plastic is installed directly on the concrete panel. The slopes are built beforehand.

- Old constructions. Good for waterproofing and renovating the old balcony or terrace floor. Liquid plastic coating raises the floor height minimally and you can still open the doors and windows. The substrate can be plywood, ceramic tiles, asphalt, concrete, PVC, TPO, PIB, polyurethane (PU), polyurea (PUA), EPDM, SBS bitumen, glass, wood, sheet metal, stainless steel, various metals and many others.

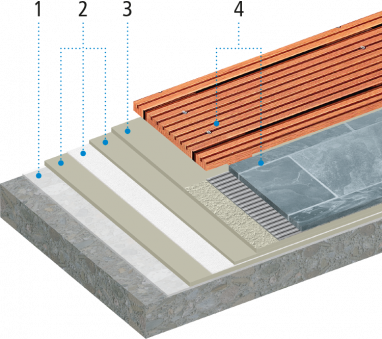

Liquid plastic system with other coating materials

Triflex BWS system is suitable for waterproofing balconies and terraces, on which it is planned to install some other traditional terrace floor finishing materials. You can use on top of waterproofing system a concrete screed, ceramic tile, paving stone, wooden board or other glued balcony flooring solutions what are suitable for this purpose. It is important to make the balcony floor waterproof because ceramic balcony floor tiles or natural stone tiles are not watertight and allow water to pass through the seams between the tiles.

Triflex BWS system is suitable for waterproofing balconies and terraces, on which it is planned to install some other traditional terrace floor finishing materials. You can use on top of waterproofing system a concrete screed, ceramic tile, paving stone, wooden board or other glued balcony flooring solutions what are suitable for this purpose. It is important to make the balcony floor waterproof because ceramic balcony floor tiles or natural stone tiles are not watertight and allow water to pass through the seams between the tiles.

The system is flexible, solvent-free, reinforced and cold-installed. Also suitable for waterproofing a inverted roof.

Replace the balcony floor tiles with a liquid plastic pattern

Balcony floor tiles may not be the best finishing solution in our climate, as the tiles tend to come off the substrate in a few years. As an alternative, we offer the Triflex BTS-P system, where with liquid plastic you can design a grid of tiles or other shapes on the surface according to your taste. Visually, the balcony covering remains the same as the real balcony floor tiles would be installed. As a top layer, we can offer a variety of options. More information on the design and layout page.

System components:

- Primer

- Reinforced waterproofing

- Wearing layer

- For example, a terrace boards or tiles

Use cases:

- Balconies, loggias, terraces, walkways and pedestrian bridges. Top coverings can be, for example, balcony floor tiles or wooden boards.

- New constructions. In the new building, waterproof liquid plastic is installed directly on the concrete panel. The slopes are built beforehand.

- Old constructions. Good for waterproofing and renovating the old balcony or terrace floor. Liquid plastic coating raises the floor height minimally and you can still open the doors and windows. The substrate can be plywood, ceramic tiles, asphalt, concrete, PVC, TPO, PIB, polyurethane (PU), polyurea (PUA), EPDM, SBS bitumen, glass, wood, sheet metal, stainless steel, various metals and many others.

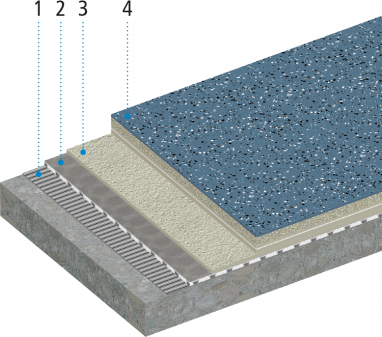

Liquid plastic system with ventilated base structure

Triflex ProDrain system main component is a decoupling membrane through which moisture can escape from substrate. It also gives system more flexibility if substrate is cracked and has slight movement. The system is designed for a situation where the substrate is damp (over 6%) and it is difficult, time consuming and expensive to dry or replace it. We install a few millimeters thick ventilation membrane on a damp surface, which allows the moisture to move out of the structure. Membrane will be covered with strong and wear-resistant layers of liquid plastic. Provides a great advantage in waterproofing renovated surfaces, as these surfaces are usually heavily soiled, cracked and damp.

Triflex ProDrain system main component is a decoupling membrane through which moisture can escape from substrate. It also gives system more flexibility if substrate is cracked and has slight movement. The system is designed for a situation where the substrate is damp (over 6%) and it is difficult, time consuming and expensive to dry or replace it. We install a few millimeters thick ventilation membrane on a damp surface, which allows the moisture to move out of the structure. Membrane will be covered with strong and wear-resistant layers of liquid plastic. Provides a great advantage in waterproofing renovated surfaces, as these surfaces are usually heavily soiled, cracked and damp.

As a top layer, we can offer a variety of options. More information on the design and layout page.

System components:

- Vapor permeable adhesive

- Ventilated decoupling membrane

- Load-bearing layer

- Waterproof and decorative layers according to the Triflex BTS-P system

Use cases:

- Balconies, loggias, terraces, walkways and pedestrian bridges. For damp and soiled substrates.

- New constructions. Suitable for substrates where moisture is expected to rise from below.

- Old constructions. For the renovation of balconies and terraces where drying or replacement of the substructure is difficult, time-consuming or expensive. A ventilation membrane is a few millimeters thick and can be installed on damp substrate and covered with strong and wear-resistant layers of liquid plastic. The edges of the membrane are left open to the outside air, through which moisture escapes from the structure. Waterproofing of a terrace or balcony with additional layers raises the floor height minimally.

Design and overlay options

For a top layer, we can offer a variety of options. More information on the design and layout page.

- Chips Design. As a top layer, we apply an even and smooth paint coating with a option to add chips

- Colour Design. The coloured fine dressing mixture spread onto suitable finish colours and then covered with varnish

- Stone Design. As a top layer, we install decorative marble and granite gravel. Fine or coarse fraction

- Creative Design. We design the top surface into a “tiled floor”. Remains visually similar to the real balcony floor tiles

- FloorTattoos. If you want the floor of your terrace, balcony or the loggia to be truly unique and interesting, we will install different shapes and logos on the finishing layers listed above.

Anti-slip balcony coating

The safety of your step on the balcony must be guaranteed as much as possible. The floor of the terrace, loggia and balcony must not be slippery. To reduce foot slipping and to achieve floor roughness, we apply sand with different grain sizes in the top coating or cover the surface with granite gravel. However, the larger the grain size, the more non-slip the floor can be, but at the same time the larger grain makes the surface of the balcony more difficult to clean.

Fire safety

We use coating materials with a higher fire sensitivity class to meet fire safety requirements where necessary.

- Material marked S1 is a flame-retardant waterproofing system: EN 13501-1: Class Cfl – s1.

- It is also possible flame-retardant waterproofing system: EN 13501-1: Class Bfl – s1.

- In the case of high-rise buildings, according to the standard EVS 812-8-2018, a floor covering material has to meet the Class A2fl – s1 requirements. To do this, the waterproofing must be covered with a fireproof material, such as concrete or tiles.

Warranty

The life expectancy waterproofing systems according to the ETA certificate is 25 years. In complete solutions, we give a 10-year guarantee for our work. By agreement, we regularly inspect and maintain the work performed, which extends the warranty period.

Triflex balcony and terrace systems properties:

- The liquid plastic material used is PMMA (polymethyl methacrylate)

- Suitable for many substrates: plywood, ceramic tiles, asphalt, concrete, PVC, TPO, PIB, polyurethane (PU), polyurea (PUA), EPDM, SBS bitumen, glass, wood, sheet metal, stainless steel, various metals and many others

- Applied in a cold liquid form. No open flames are used during installation

- Installation of reinforced waterproofing on the entire surface. All systems except Triflex BFS

- Aluspinda ventileeriv. Konstruktsiooni jäänud niiskusel on võimalik läbi ventilatsioonimati välja liikuda. (Triflex ProDrain). Kasutatakse, kui aluspinna niiskus on üle 6%

- Substrate ventilating. It is possible to remove moisture through the ventilation membrane. (Triflex ProDrain). Used in cases when the moisture content of the substrate is more than 6%

- Elastic and crack-bridging

- Hydrolysis resistant. Suitable for zero slope surfaces, as it does not react with water and can withstand standing water

- Alkali resistant. Tolerates mineral materials

- Mechanically strong and wear-resistant. Resistant to high mechanical loads and point loads of table and chair legs on the floor without breaking the ground

- Fast-curing. You can walk on the floor as early as 1 hour after the end of the work.

- Minimal application temperature is 0°C

- Seamless, which further eliminates the possibility of water penetration

- Rain proof after 30 minutes

- Weather proof (UV, IR, etc.)

- European Technical Assessment according to ETAG 005 with CE mark

- Fire classification in compliance with EN 13501-1: Class E

- S1 version is a flame-retardant waterproofing system: EN 13501-1: Class Cfl – s1

Contact us or come to visit

If you need advice or help from men who just don't talk but actually do, write or call us.